Answer: Most lubricating oils have other chemicals added to improve the overall performance of the fluid. Chemical additives are used to enhance the beneficial properties of the base oil or to make up for oil deficiencies. For passenger car motor oils, base oil makes up 70 to 80 percent of the final product; the other 20 to 30 percent is comprised of additive chemistry.

Additives help lubricants stand up to extreme operating environments. Even the best base oil would not be able to protect as well against the effects of heat, shearing forces, chemical and water dilution, corrosion and wear particles. In short, additives make good base oils even better. They give good base oils the performance benefits consumers have come to expect, such as multi-grade performance, extended drain intervals and extreme-pressure performance.

Anti-wear Agents chemically react to form a film barrier that prevent metal-to-metal contact and wear.

Antioxidants reduce the tendency for oil to react with oxygen and reduce sludge buildup.

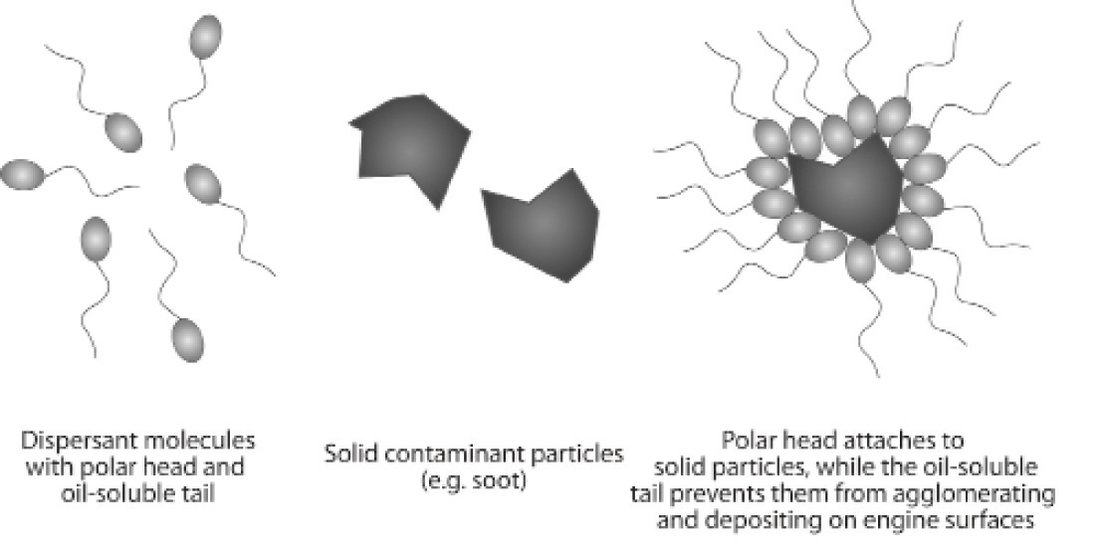

Dispersants help suspend and disperse contaminants in the oil to keep engine surfaces free of sludge and deposits. They fight the build-up of corrosive acids and are most efficient at controlling low-temperature deposits.

Detergents help suspend and disperse contaminants in the oil to keep engine surfaces free of sludge and deposits. They are most efficient at controlling high-temperature deposits.

Extreme-Pressure Additives coat metal surfaces to help prevent close-contact components from seizing under extreme pressure. They are activated by high temperatures and high loads to react with the metal’s surface to form a sacrificial wear layer on components.

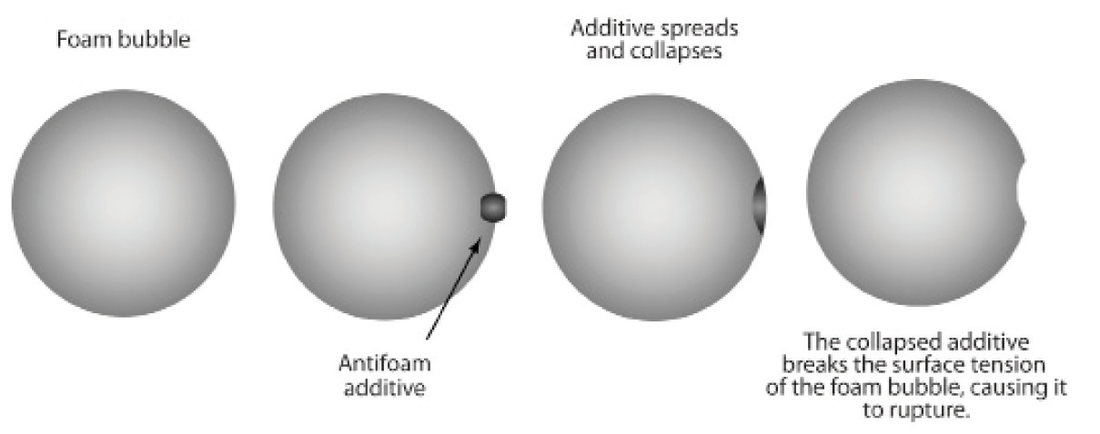

Foam Inhibitors reduce the surface tension of air bubbles and causes them to collapse.

Friction Modifiers can be used to give oil more 'slippery' characteristics. In engine oils, friction modifiers are used to increase the oil’s lubricity for the purpose of reducing friction and improving fuel economy.

Pour Point Depressants give high-viscosity oils good low-temperature properties. Pour point depressant polymers inhibit the formation of crystals to minimize low-temperature viscosity increase.

Rust & Corrosion Inhibitors form a protective barrier over component surfaces to seal out water and contaminants. While most rust and corrosion inhibitors work by forming a physical barrier, some rust inhibitors function by neutralizing acids.

Viscosity Index (VI) Improvers are long-chain polymers that help control the viscosity of multi-grade engine oils. They expand and contract as temperatures vary. High temperatures cause VI improvers to expand and reduce oil thinning; low temperatures cause VI improvers to contract and have little impact on oil viscosity.

AMSOIL is available at Rivord Repair Center they are open from 7 a.m. to 5 p.m. Monday through Friday and Saturday by appointment. For more information call 715-718-2727 or stop by the center at 1327 Ogden Ave, Superior Wi 54880

Additives help lubricants stand up to extreme operating environments. Even the best base oil would not be able to protect as well against the effects of heat, shearing forces, chemical and water dilution, corrosion and wear particles. In short, additives make good base oils even better. They give good base oils the performance benefits consumers have come to expect, such as multi-grade performance, extended drain intervals and extreme-pressure performance.

Anti-wear Agents chemically react to form a film barrier that prevent metal-to-metal contact and wear.

Antioxidants reduce the tendency for oil to react with oxygen and reduce sludge buildup.

Dispersants help suspend and disperse contaminants in the oil to keep engine surfaces free of sludge and deposits. They fight the build-up of corrosive acids and are most efficient at controlling low-temperature deposits.

Detergents help suspend and disperse contaminants in the oil to keep engine surfaces free of sludge and deposits. They are most efficient at controlling high-temperature deposits.

Extreme-Pressure Additives coat metal surfaces to help prevent close-contact components from seizing under extreme pressure. They are activated by high temperatures and high loads to react with the metal’s surface to form a sacrificial wear layer on components.

Foam Inhibitors reduce the surface tension of air bubbles and causes them to collapse.

Friction Modifiers can be used to give oil more 'slippery' characteristics. In engine oils, friction modifiers are used to increase the oil’s lubricity for the purpose of reducing friction and improving fuel economy.

Pour Point Depressants give high-viscosity oils good low-temperature properties. Pour point depressant polymers inhibit the formation of crystals to minimize low-temperature viscosity increase.

Rust & Corrosion Inhibitors form a protective barrier over component surfaces to seal out water and contaminants. While most rust and corrosion inhibitors work by forming a physical barrier, some rust inhibitors function by neutralizing acids.

Viscosity Index (VI) Improvers are long-chain polymers that help control the viscosity of multi-grade engine oils. They expand and contract as temperatures vary. High temperatures cause VI improvers to expand and reduce oil thinning; low temperatures cause VI improvers to contract and have little impact on oil viscosity.

AMSOIL is available at Rivord Repair Center they are open from 7 a.m. to 5 p.m. Monday through Friday and Saturday by appointment. For more information call 715-718-2727 or stop by the center at 1327 Ogden Ave, Superior Wi 54880

RSS Feed

RSS Feed